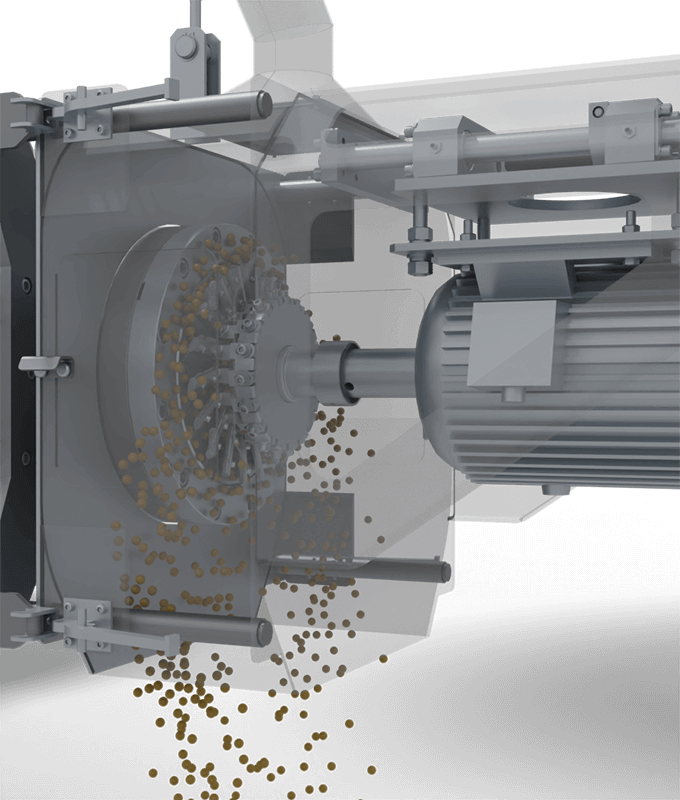

In aquafeed production, minimizing waste is key to improving profitability. FAMSUN introduces an advanced solution with its Twin-Screw Aqua Extruder, a high-performance fish feed extruder machine designed to enhance efficiency while reducing costs. With its optional preconditioner waste control function, this extruder significantly reduces startup losses, improving material utilization from the very first batch.

Optional Waste Control Function

The standout feature of the FAMSUN Twin-Screw Aqua Extruder is its optional preconditioner waste control system. This function reduces startup waste by approximately 70%, allowing producers to conserve raw materials that would otherwise be lost during machine warm-up. It’s an ideal choice for manufacturers focused on cost control and sustainability.

Boost in Raw Material Utilization

Thanks to its optimized control and precise processing, this fish feed extruder machine helps producers maximize the value of every ingredient. By reducing unnecessary waste, more raw material is transformed into sellable product, directly contributing to higher production yields and improved bottom lines.

Lower Production Costs

With less startup waste and better raw material efficiency, overall production costs are significantly lowered. The result is a leaner, more cost-effective manufacturing process—without compromising feed quality or operational stability.

Conclusion:

The FAMSUN Twin-Screw Aqua Extruder offers more than just high-quality feed processing—it provides real savings through innovative waste reduction. As a forward-thinking fish feed extruder machine, it helps aquafeed producers stay competitive by cutting costs and boosting efficiency from start to finish.